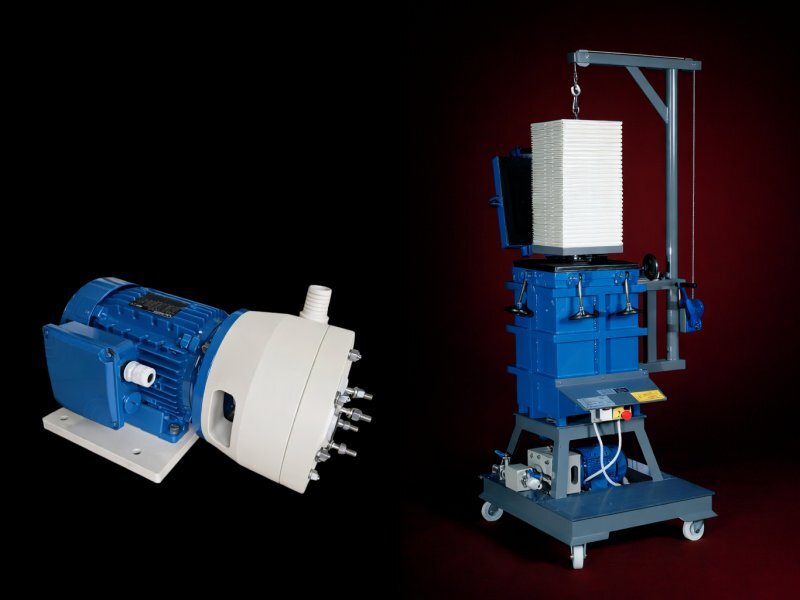

Restart of electroplating plants – filter and unit pumps

Mistakes and best practices

Restarting electroplating plants after the Christmas break is a critical moment for filter and unit pumps—components that, during extended shutdowns, undergo the greatest "invisible" stresses that can lead to significant negative consequences.

Dry running, sediment build-up, crystallization, and material stress can compromise performance within the very first hours of restart, with direct effects on the equipment and indirect effects on bath quality and production continuity.

As recommended during commissioning of our machines at customer sites, before stopping the plant it is necessary to drain the filter pump of the electrolytic solution and fill it with water.

This simple operation helps prevent serious damage when the plant is restarted.

Most common issues after a plant shutdown

Dry start-up of filter pumps, which can damage the mechanical seal and gaskets

Crystallization and sediment in the circuits, which can lead to damage to unit pump components, increased pressure, and reduced flow rate

Exhausted filter media, resulting in reduced flow rate, increased pressure on the unit pump, and consequently compromised electroplating bath quality.

Discover the key essential tips for a safe restart by copying and pasting the link:

https://mailchi.mp/2f2431bc1998/ripartenza-impianti-galvanici-pompe-filtro-e-gruppi-pompa-11045026